-

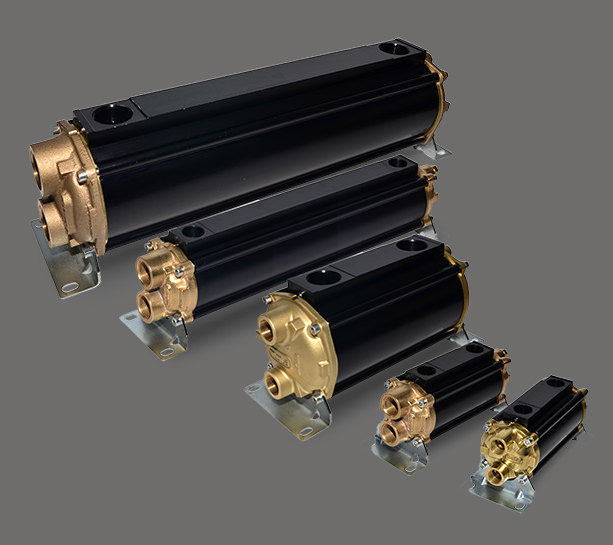

CONCEPTION ET FABRICATION

de systèmes d'échange de chaleur

-

conception et fabrication

de systèmes d'échange de chaleur

-

CONCEPTION ET FABRICATION

de systèmes d'échange de chaleur

Culture &

valeurs

Mieux nous connaitre

Le groupe MOTA est spécialisé dans le refroidissement tubulaire. Configuration simple ou complexe, contraintes modérées ou extrêmes, quel que soit votre besoin de refroidissement, nos équipes vous apportent une solution pertinente, efficace, rapide et économique.

Actualités

Pour tout savoir

Salon Japan International Boat Show

Mars 2024. Salon Japan International Boat Show En partenariat avec Mizuno...

LireMOTA rejoint la convention des entreprises pour le Climat 2024

Mars 2024 . MOTA rejoint le CEC Provence Méditerranée.Cette adhésion témoigne...

LireUN EXERCICE INCENDIE INSTRUCTIF.

07 février 2024 : Une collaboration fructueuse entre le Centre de Formation...

Lire29 octobre 2023 : L'équipe MOTA RUNNING au Marseille Cassis...

29 octobre 2023 : Bravo à toute l'équipe MOTA Running, pour avoir représenté...

LireMOTA industrie 4.0

Octobre 2023 : MOTA est heureuse de vous présenter son nouveau collaborateur...

LireMOTA organise sa 1ère fresque du climat

Octobre 2023 : 40 personnes, 42 cartes, 3 heures et 1 défi...comprendre et...

LireMOTA élue meilleure entreprise familiale de l'année en région Sud-Est

Septembre 2023 : MOTA remporte le trophée de l'entreprise familiale de l'année.

Lire